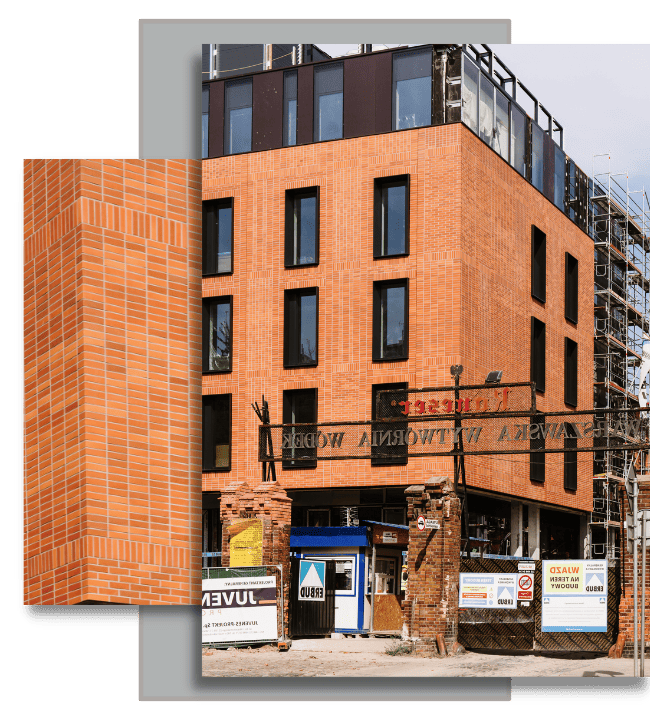

We know all about brick

The scope of our specialist and contractor services:

Substantive support and full assistance in the selection and development of the optimal detailed design of facades made of clinker, hand-formed and concrete facing bricks to meet all investor criteria and technical and technological requirements,

Fast and comprehensive service in the field of professional construction of elevations in the masonry and precast concrete system, and we provide full service in the entire scope of the commissioned work, from taking measurements to preparing the construction site,

The highest level of service. We carry out the investment in accordance with the guidelines of the project, the requirements of the architect, always under the supervision of our experienced manager and project manager, we also respect the unusual wishes of the investor,

Continuous quality control. We maintain weekly reporting on the progress of construction of façade works enriched with photographic documentation and a detailed description of the work in progress,

Support at every stage of the investment. We provide assistance with all acceptance procedures.

We have specialized in clinker face masonry for more than twenty years.

We provide our investors with:

Professional preparation and protection of the construction site (we are self-sufficient and create our own facilities for the elevation work we carry out).

Precise delivery of the right amount of construction facade materials (we can provide delivery of any type of face bricks that are available on the market).

Experienced team(all our works are carried out by masons with many years of experience, always under the supervision of qualified work managers).

Supervision of our section of work at each stage of construction (we conduct constant supervision of the work in progress to ensure the highest possible quality and guarantee for the facades implemented).

Optimization of the entire process of preparation and execution of elevations (at each stage of the investment we support both the investor and the designer, help in the selection of materials, solving unusual execution details).

We build with vision

1 of 3We know all about brick

2 of 3Stylishly create facades

3 of 3We have realized more than 300,000. m2 of facades faced with clinker

List of Frequently Asked Questions (FAQ):

The most popular questions about the implementation of projects in the technology of facing brick (clinker, ceramic, concrete) or clinker façade tile. If you have any other questions, please contact us by phone or email:

How do you line the facade with clinker tiles?

How to prepare the substrate for clinker tile facing?

How to properly make a clinker brick facade?

How to start bricklaying a clinker wall?

What facade materials do we use when facing walls with clinker?

In our work, we use only brand-name adhesives and grouting compounds from reliable suppliers. We use only proven, tested products. Each facade material has different technological requirements, so it remains on our side to decide on the components for brick and clinker tile. We work on our own and entrusted materials, as long as they are approved by us. We do not use façade materials from an uncertain source, cheap "market" mortar products of unknown origin, or out-of-date and improperly stored products (damaged, caked and soggy).

How do we account for the elevation work performed?

- It is customary to make the final settlement on the basis of an as-built protocol made on the basis of as-built measurements of the facade measured after the grouted surface. In addition, facade corners and glyphs (in the case of tiling) are accounted for. Window openings of less than 1m2 are not subtracted from the area of the completed facade. The basic rate is increased for non-standard work (openwork masonry, cornices, faults and façade breaks). We allow billing based on a lump sum, but in this case it is necessary to have accurate detailed detailed design documentation as a basis for estimating the area of the facade (in case of changes in the design, the lump sum rate is also subject to change).

How do we solve the problem of facade scaffolding?

- All of our employees have the appropriate safety and height training, for work on scaffolding. We have our own professional facade scaffolding that we can use for our facade work. Billing for the supply, installation, lease and dismantling of scaffolding is accepted per square meter of scaffolded facade. Of course, we can use approved scaffolding from the investor or general contractor.

What technical background do we have in making clinker and architectural concrete facades?

- On each of our elevation projects we create our own technical and social facilities. We use our own residential and storage containers, which we deliver to the construction site with our own transport. What we need from the developer is the provision of water for technical purposes and electricity to power power tools and construction winches attached to scaffolding.

We are trusted by the biggest players in the construction and contracting industry.