Glossary of basic elevation terms used in the construction industry:

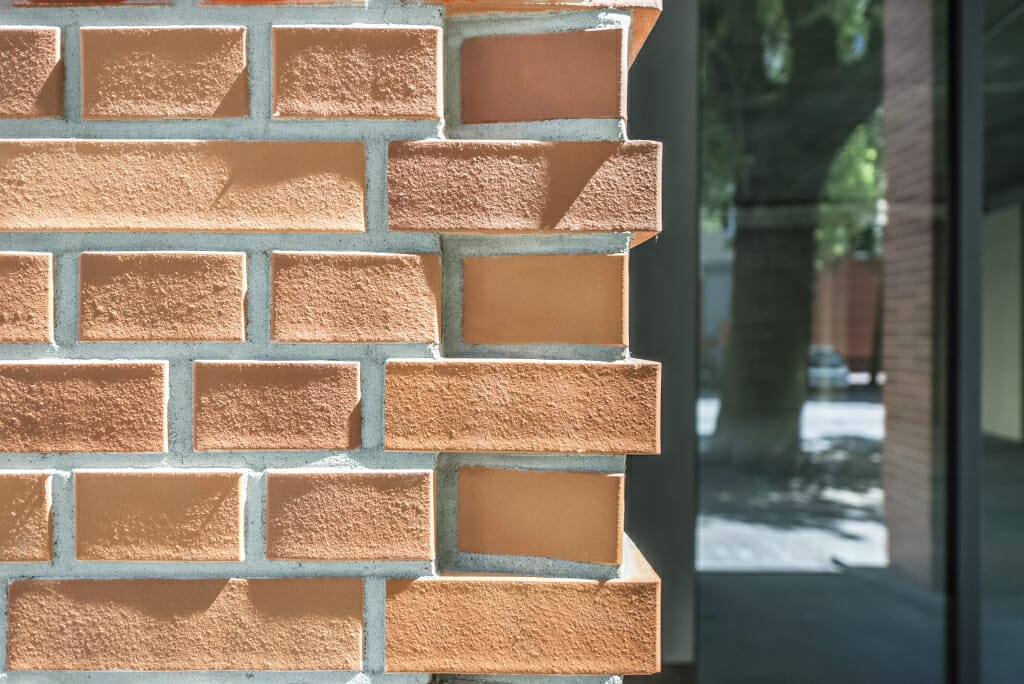

Clinker brick – a decorative variety of traditional facade building bricks, in contrast to which it can be of any color and texture. It comes in many sizes length 20-50cm, width 5-12cm, height . However, the most important distinguishing feature of clinker brick is its decorative surface. The face of the brick can be smooth (pressed or imprinted), porous, corrugated, broken, glazed, hand-formed, sandblasted. The choice of designs and textures is virtually unlimited. It creates a very strong and resistant to fire, mechanical damage and dirt facade plane. The lifespan of clinker brick as a facade material is unlimited. The material consumption per square meter of facade is about 40-65 pieces, depending on the size of the brick. A facade made of clinker bricks is a ventilated facade, meaning it allows air exchange and the removal of moisture from inside the wall.

Clinker tile – sister of clinker brick with the same face appearance as brick. Many commercially available clinker tiles are modeled after commercially available clinker bricks. The tile can be pre-cut from brick or molded from scratch as an imitation of real brick. Its advantage is its light weight, allowing it to be glued directly to the thermal insulation, reducing the cost of the facade. In order to make the tiles as similar to bricks as possible, there are commercially available corner shapers that allow to completely abandon the traditional making of corners by joining two tiles at the corners. The great advantage of a facade made of clinker tile is its high resistance to mechanical damage and ease of repair of any damage.

Grout for brick clinker façade – specially designed for grouting brick and clinker tile façade with chemical properties neutral to clinker. In addition to the proper conduct of construction work, the correct choice of mortars for clinker minimizes the possibility of efflorescence on the facade. These efflorescences are the result of a chemical reaction between the components of the mortar and the brick under conditions of high humidity. The typical width of a grouted joint generally falls within 8-12mm, depending on the facade layout.

One-step brick laying – a technique of building facades in which the bricklayer, laying individual layers of bricks, at the same time forms the joint filling grout. The color of the grout must be decided before the masonry work begins, preferably all the grout needed should be delivered to the construction site, since subsequent production batches may differ minimally in shade. Another disadvantage, is that each mason on his section of work will have his own way of molding the grout.

Two-stage m asonry – a masonry technique that allows the main mortar to be separated from the joint-filling grout, allowing the wall to dry faster. In one-step masonry, the actual mortar is used to make the grout also forms the joint. With two-stage masonry, the color of the joint filling can be matched to the final appearance of the already completed wall by making grout samples in all the colors and shades that the investor is considering.

Precast concrete facade – an increasingly popular element on the market for interior decoration and building facades. It allows you to achieve any decorative effect on walls and ceilings (color, size, texture, perfect plane or no plane at all, wavy, any carving or even relief). Made to size using industrial technology and delivered to the construction site as a finished product to be attached to any supporting wall or structure. They can be attached to the ground in several ways. They can be glued directly to a pre-prepared substrate, such as OSB, screwed with dowels glued into holes in the wall proper, or hung on system mounting consoles.

GRC slabs – a flat precast concrete product about 2-3 centimeters thick and ranging in size from 50cm to as much as 4 meters designed for decorative facades. It comes in a variety of type sizes, different textures and colors. It is attached to the facade using a properly designed anchor system or on a properly designed steel substructure.

Substructures and facade fastening system – is a way to support the wall facing the facade on the structural wall consists of elements that stabilize the wall layers against each other. The complete system consists of stainless steel or galvanized steel anchors, specially prefabricated flat truss reinforcements, so-called. masonry and starting consoles supporting the lowest brick layer of the facing wall.

Anchors for three-layer walls – specially shaped threaded steel rods that make it possible to permanently bind the structural walls of the building to the decorative layer of clinker bricks facing the facade. They are fixed with one end in drilled holes in the structural wall with special adhesives, and with the other they are embedded in the joint of the decorative brick wall. The length of such an anchor allows at the same time to place in the thickness of the masonry thermal insulation and a ventilation gap that allows micro-circulation of air and removal of any moisture that accumulates in the masonry.

Starting consoles, intermediate consoles – specially designed “to size” stainless steel profiles that allow the facing wall to be stably supported on the load-bearing structure of the building, while maintaining a distance that allows the installation of thermal insulation. They are used to support the facing wall in situations where it is not possible to support it on a stable foundation. They allow the installation of hanging lintels over window and door openings.

Murfor – a flat reinforcing element used for mechanical reinforcement of the outer layer of three-layer walls in areas exposed to high mechanical loads or vibrations. An arrangement of specially designed thin reinforcing bars or flat bars forming a flat truss makes it possible to make lintels over works without the use of consoles, and also strengthens and stiffens large facade planes. After adding the appropriate stirrups to the masonry, it is possible to decoratively brick the overhanging elements of the facade like lintels laid on the so called “masonry”. “roll”

Expansion joint – an indispensable part of the technology of making walls faced with clinker bricks. It protects the plane of the facade from possible cracks in the bricks resulting from the settling process of newly constructed buildings. Fill the expansion gaps with an expansion tape that matches the color of the facade. The distribution of slots is based on technological requirements and the size of the building mass.

elaborated: Adam Powojewski